CNC Milling | CNC Turning | Conventional Turning | Stud-Welding | Inspection

At Arcot Engineering we offer the following precision machining services :- CNC Milling; CNC Turning; Conventional Turning; Stud Welding and Inspection

Precision Milling

We offer 3, 4 & 5 axis precision milling of a wide range of materials including inconel, stainless steel, aluminium to tolerences to fine limits using 11 of our available machines individually listed under out plant section.

We can also take care of many of your post processes:-

- heat treatments

- anodising

- laser marking

- engraving

- pressure testing as required

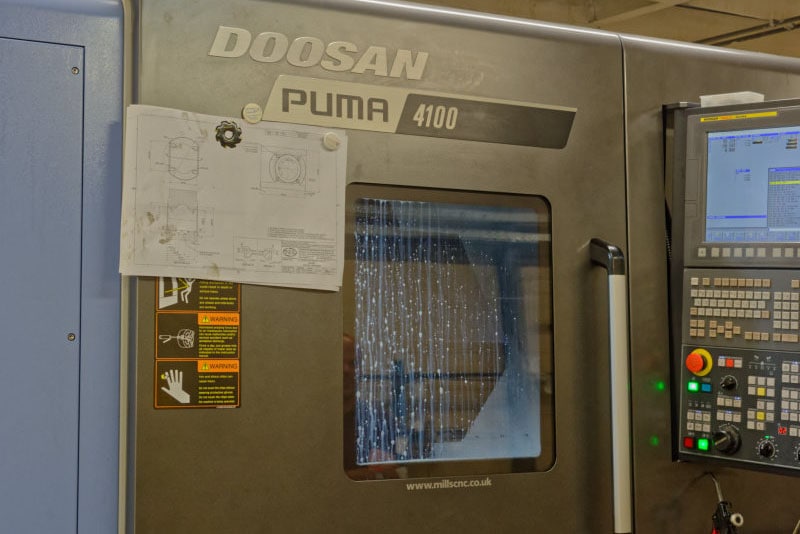

Precision Turning

We have 8 dedicated CNC turning machines on site listed individually under our plant section. We work with a wide range of materials including inconel, stainless steel, aluminium to tolerences to fine limits and finished to your requirements. Again taking care of many post machining requirements :-

- heat treatments

- anodising

- laser marking

- engraving

- pressure testing as required

- precision grinding

Inspection

We have an on site inspection facility to ensure that tolerences and specification are met prior to despatch. This is accomplished with:-

- Trimos vertical 3

- Trimos vectra touch

- Aberlink CMM model AX10M TOO 600

- Bruker S1 Titan/Tracer 5/CTX PMI gun

Traceability

We maintain a Bruker S1 Titan/Tracer 5/CTX PMI gun and can test and trace machined pieces from start to finish. All jobs leaving Arcot Engineering with be accompanied by a full report from the PMI gun along with all of the other required information and certificates.

Conventional Turning

We have a conventional turning facility for when it is not cost effective to produce on CNC Lathes and for producing parts for internal jigs & fixtures.

Stud Welding

Stud welding to components per customer requirements

Lumsden Grinding

Large surface grinding for removal of metal from profiles and large plates.